research and developmen

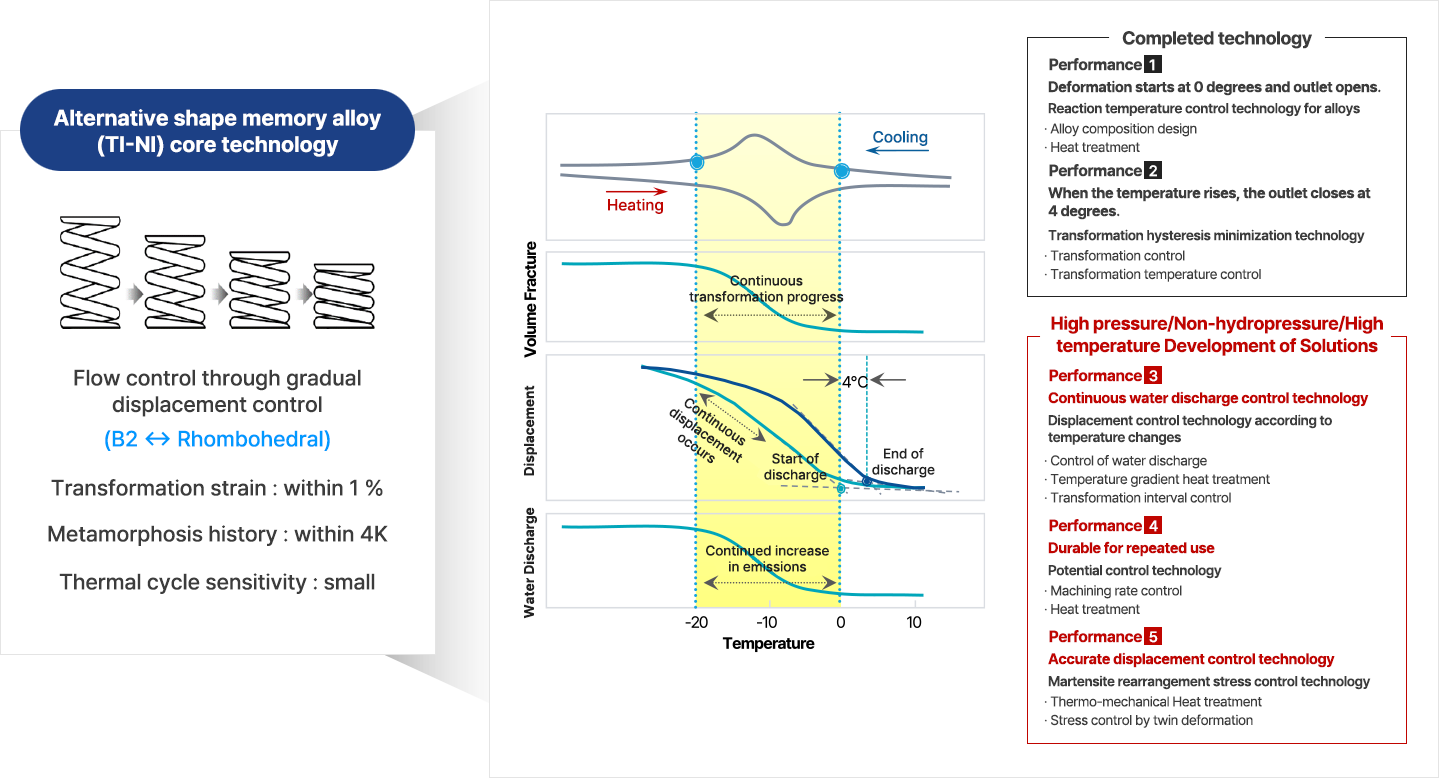

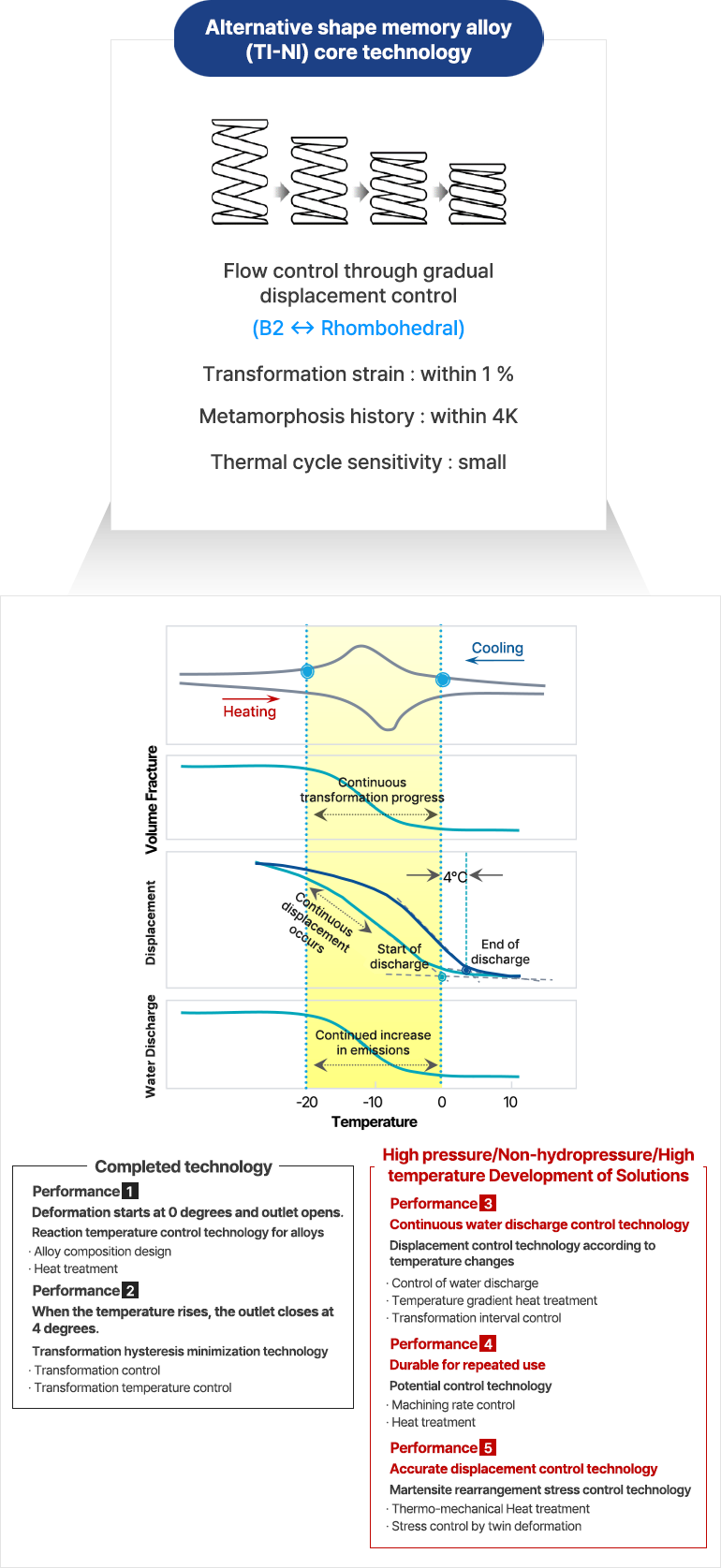

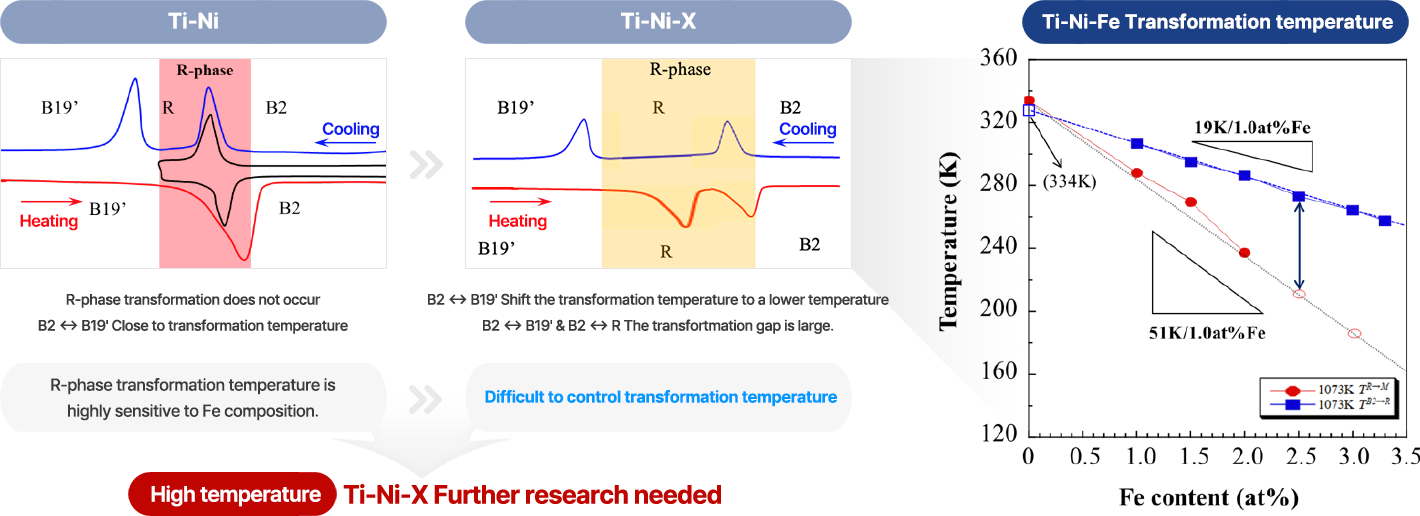

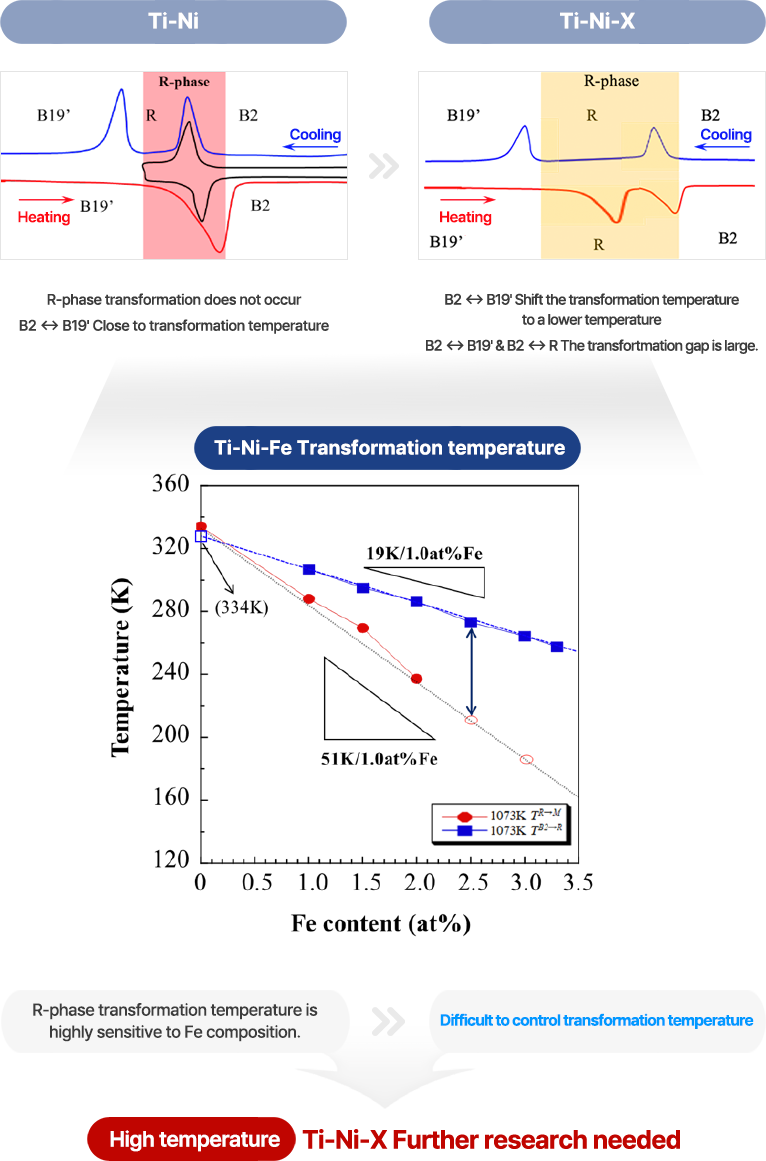

For high pressure·Non-hydrostatic pressure·High temperature B2 ↔ Rhombohedral

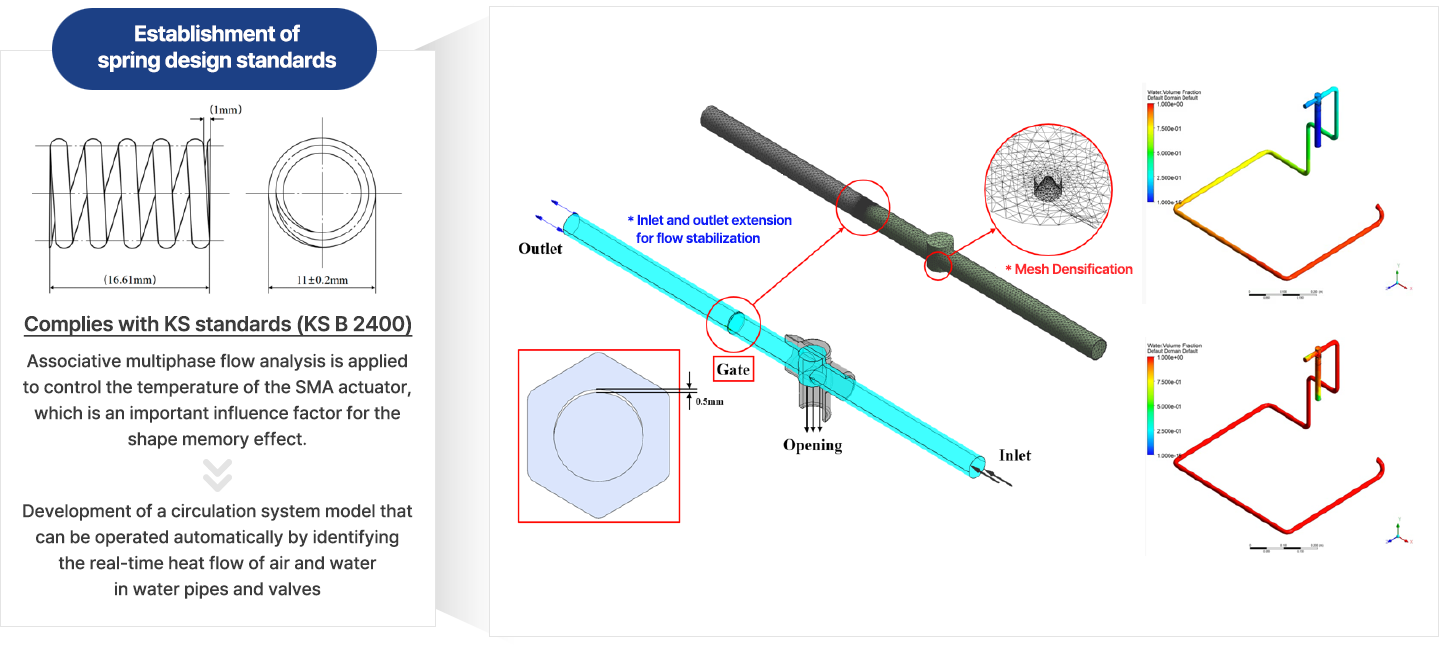

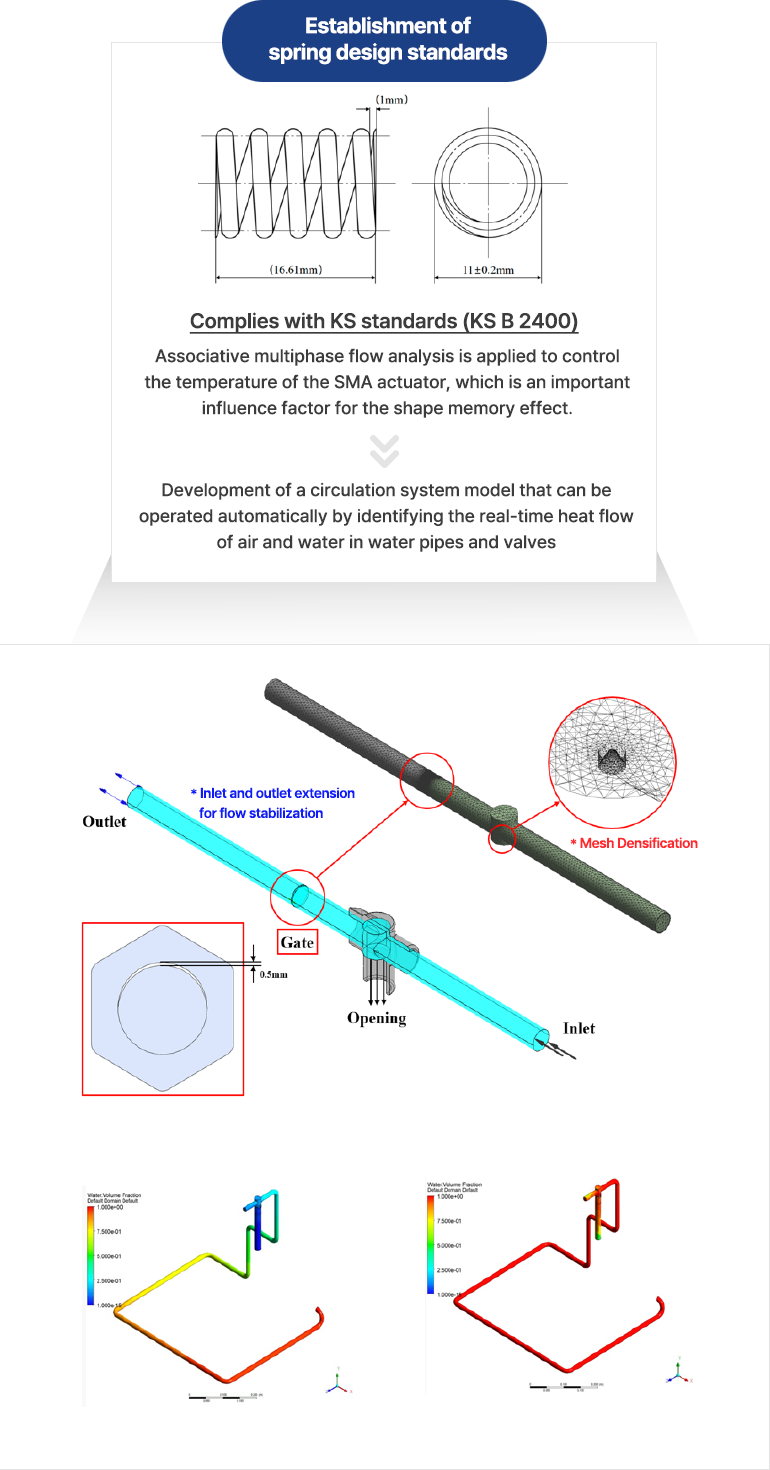

Development of Rhombohedral Transformation Control Technology

Performance 1

Deformation starts at 0 degrees and outlet opens (Completed technology)

Reaction temperature control technology for alloys – development of optimal alloy composition and heat treatment conditions

Alloy composition design (addition of third element), establishment of heat treatment conditions

Performance 2

When the temperature rises, the outlet closes at 4 degrees (Completed technology)

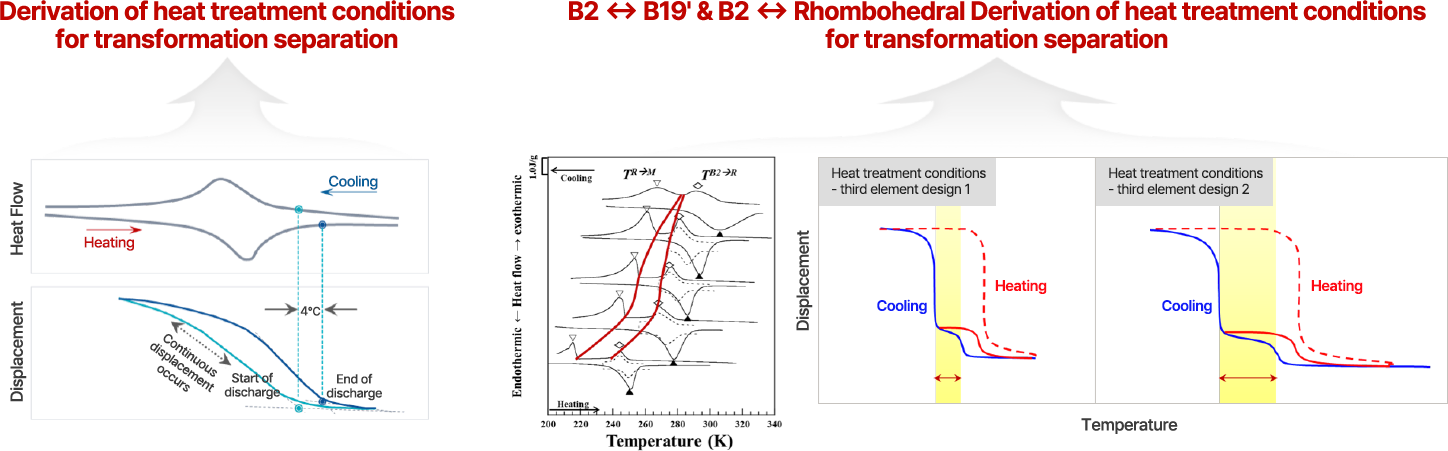

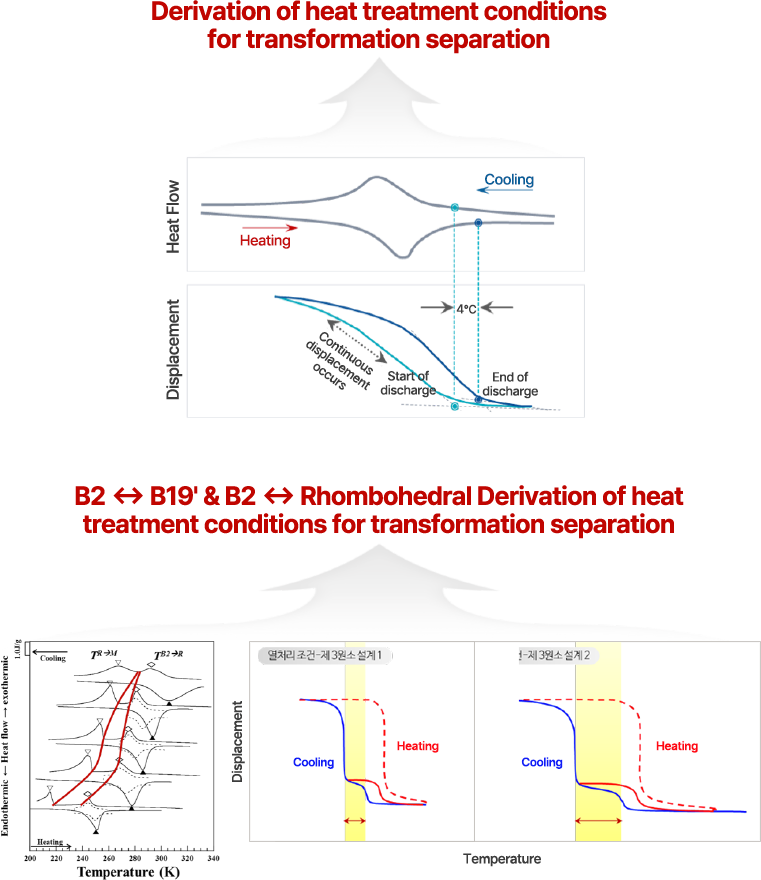

Transformation hysteresis minimization technology

❶ Minimize transformation history (0 ℃ OPEN 4 ℃ CLOSE)

❷ B2 ↔ B19’ & B2 ↔ Rhombohedral transformation separation

Performance 3

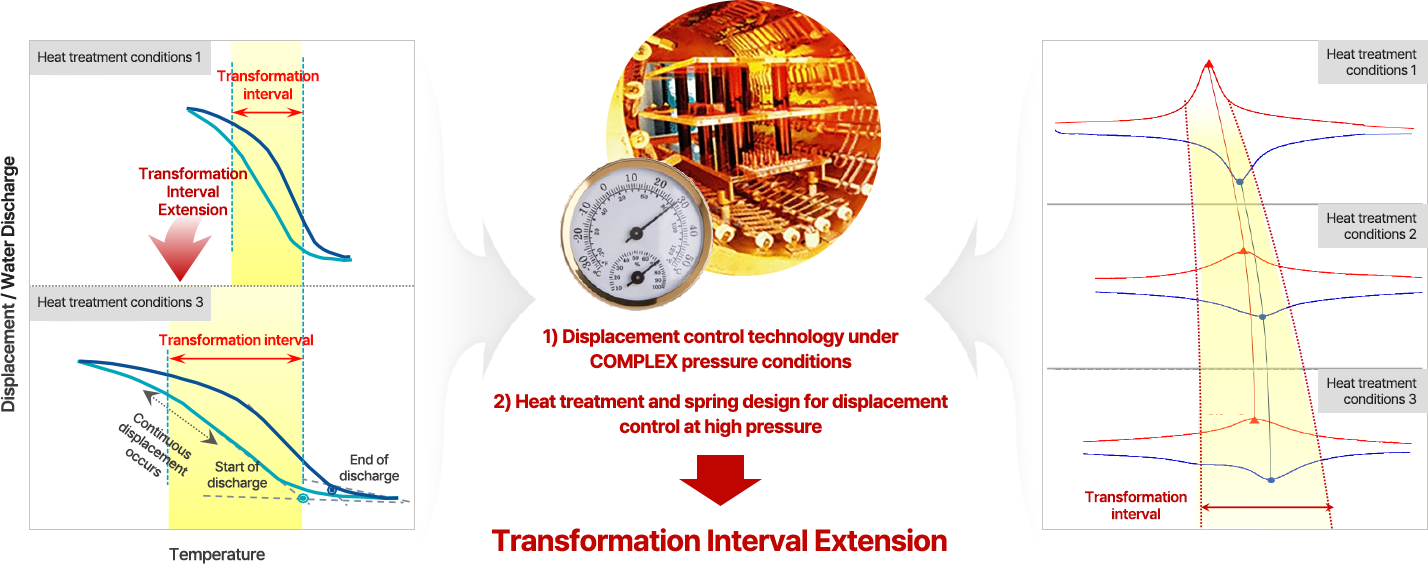

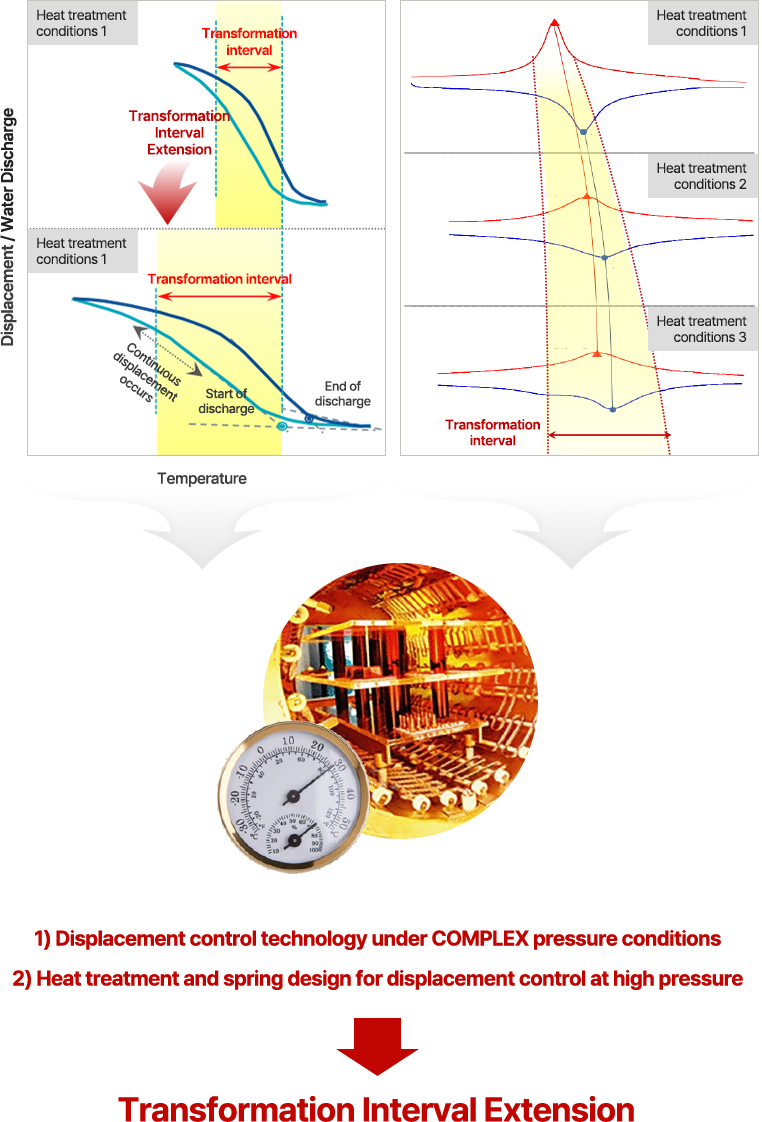

Controls water discharge by continuously generating displacement

R-phase transformation interval expansion ▶ Continuous displacement generation ▶ Continuous increase in water discharge For high pressure use

For Non-hydraulic For Pressure use

Spring design, temperature gradient heat treatment, and transformation interval control according to valve usage conditions.

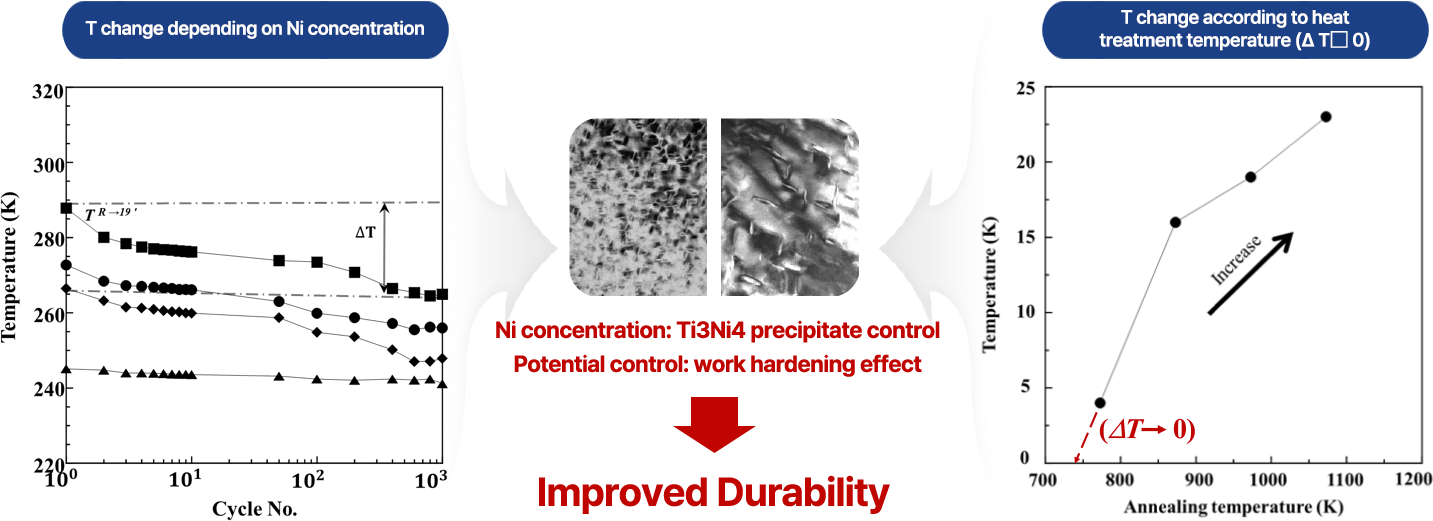

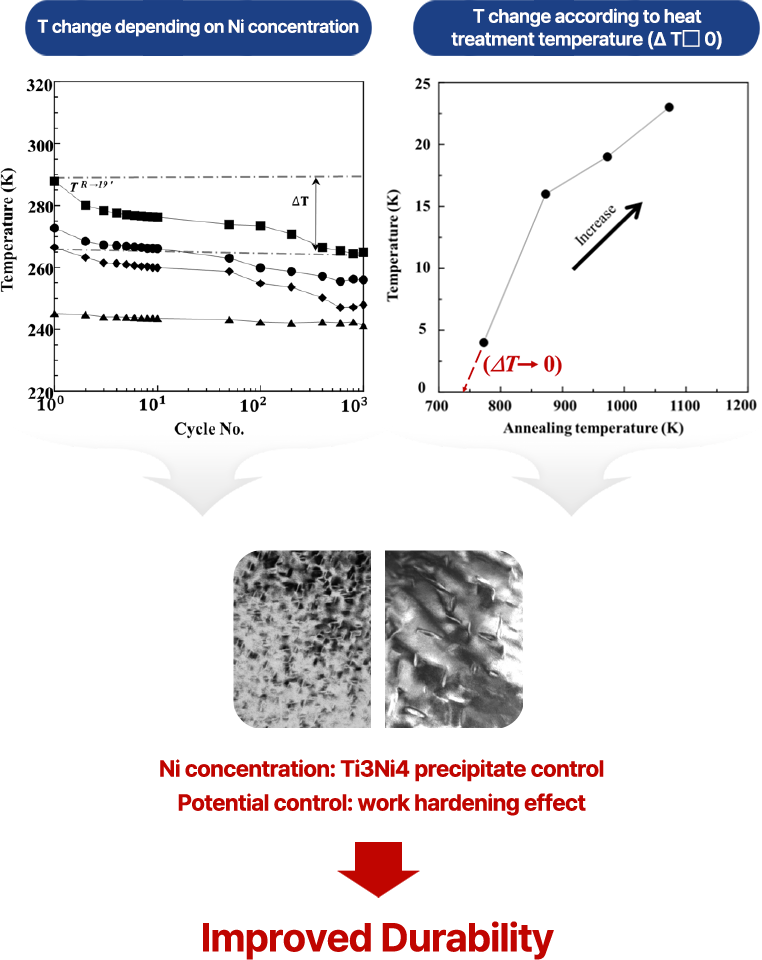

Performance 4

Durable for repeated use

Improved durability so that there is no change in valve opening/closing temperature even after repeated use

For High pressure For Non-hydrostatic For High temperature

❶ Ti3Ni4 precipitate control - optimal aging temperature and time

❷ Potential control - development of processing conditions and thermomechanical processing

Performance 5

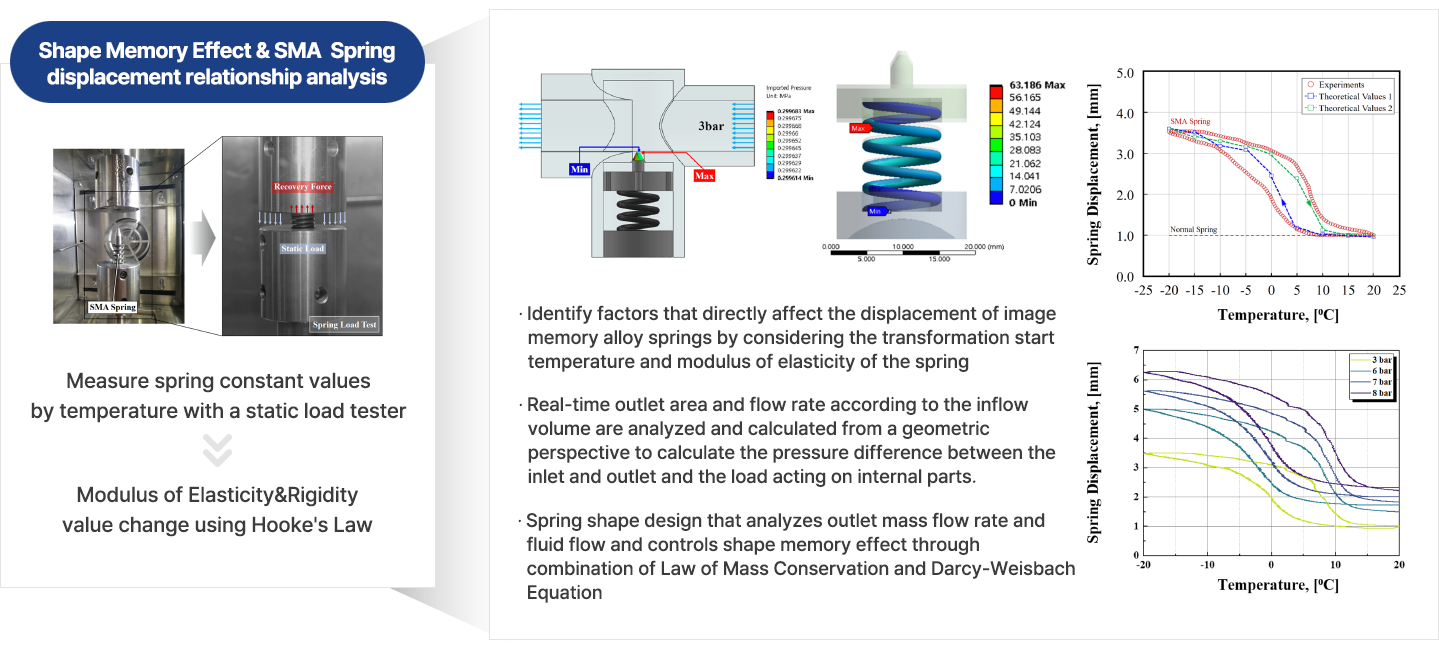

Accurate spring displacement control

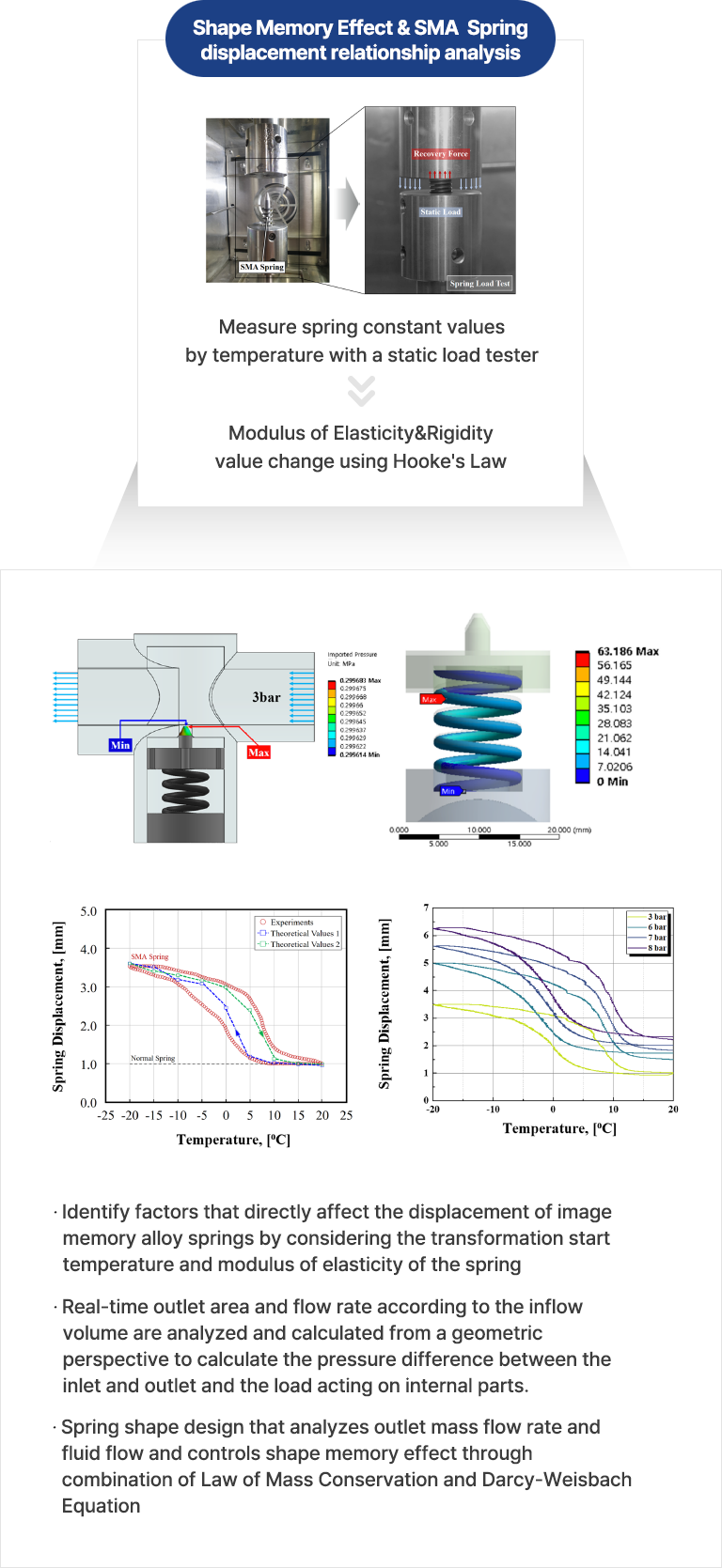

Accurate displacement occurs at appropriate temperature under high pressure (4~6bar) and bias spring conditions

>For High pressure For Non-hydrostatic For High temperature

Derivation of spring displacement values through linear-nonlinear structural analysis

Performance 6

Control of total fine flow discharged per hour

Emission prediction technology through multi-phase flow analysis

For High pressure For Non-hydrostatic

Linked analysis using Fluid-Structure Interaction & Multiphase Flow Methods